Processing

Micronizing Mill

Precision micronizing mill systems designed for fine grinding of limestone materials.

- ✓ Precise Size Control

- ✓ High Efficiency Grinding

- ✓ Durable Construction

- ✓ Easy Maintenance

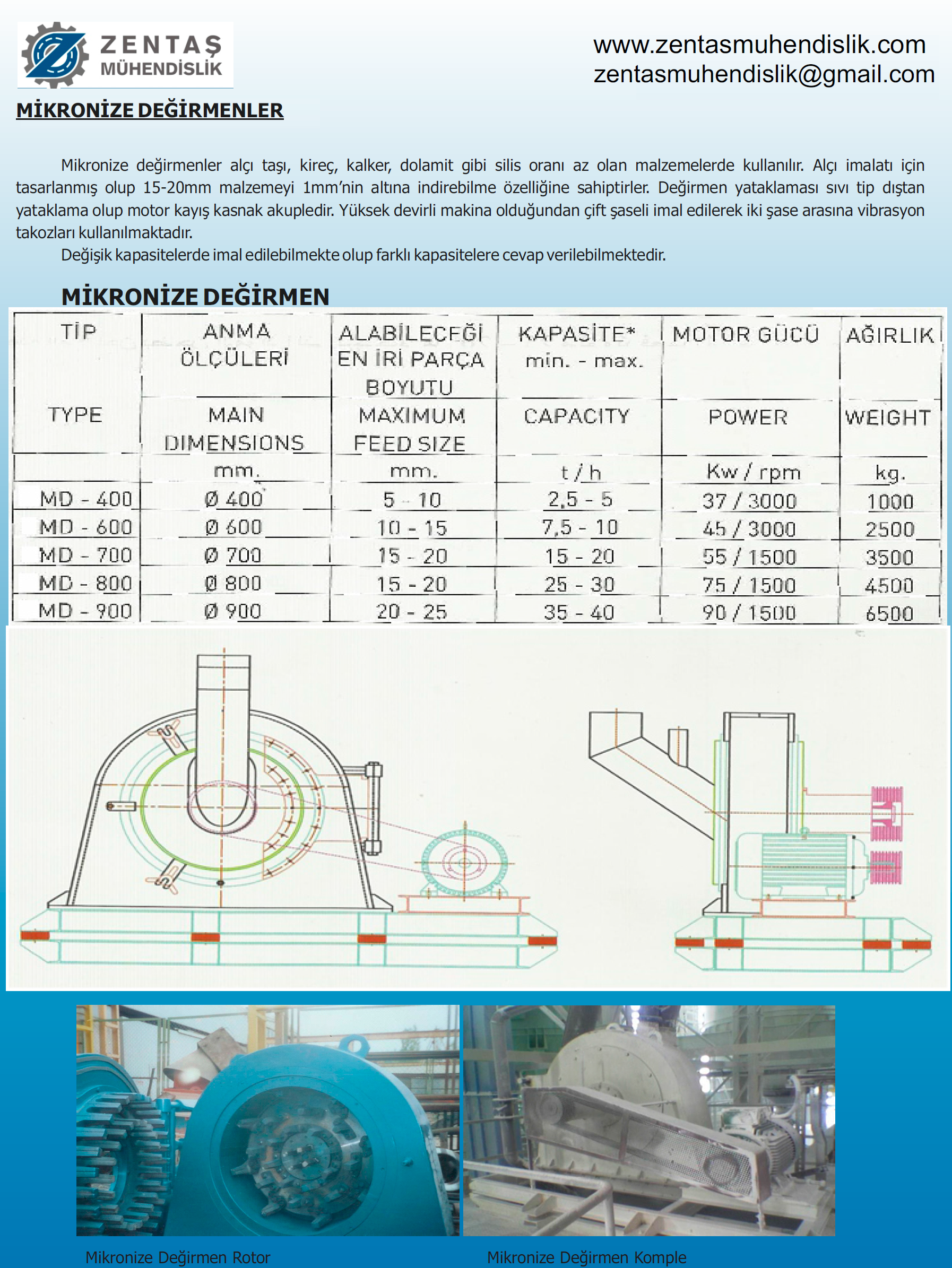

Micronizing Mill

The micronizing mill is specifically used for micronizing limestone materials in the 0-15 mm range.

Technical Features

- Precise size control

- High-efficiency grinding system

- Durable material construction

Applications

- Fine grinding of limestone and similar minerals

- Industrial material processing plants

- Raw material preparation and homogenization

Advantages

- Precise control of material size

- High-efficiency grinding

- Homogeneous and quality product output

- Low maintenance requirements

- Long-lasting design

Product Features

Precise Size Control

Homogeneous filler and mineral filler production with precise grinding in 0-15 mm range.

High Efficiency Grinding

Modern mill technology ensures minimum energy consumption with maximum production capacity.

Durable Construction

Special alloy cast housing and replaceable liners provide long service life and wear resistance.

Easy Maintenance

Modular design enables fast spare parts replacement and minimum downtime.

Technical Specifications

Grinding Range 0-15 mm micronized

Capacity 5-20 tons/hour (material dependent)

Material Limestone, calcite, dolomite, marble

Grinding Type Impact + friction effect

Housing Material Special alloy wear-resistant cast

Control Automatic feeding + vibration monitor