Automation

Weighing & Dosing Systems

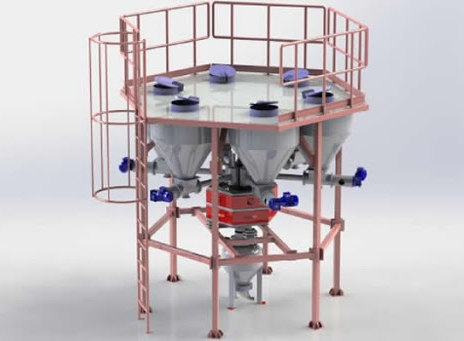

Precision weighing and automatic dosing systems for industrial facilities.

- ✓ Precise Weighing

- ✓ PLC Automation

- ✓ Multi-Material

- ✓ Data Monitoring

Weighing & Dosing Systems

Our company produces systems suitable for weighing and dosing all materials in industrial facilities.

Technical Features

- High-precision load cell systems

- PLC-controlled automation

- Touch operator panel

- Multi-material management

- Remote monitoring and control capability

System Components

- Electronic weighing systems

- Automatic dosing units

- Material feeding conveyors

- PLC control unit

- SCADA monitoring software

Application Areas

- Asphalt and concrete batching plants

- Chemical processing facilities

- Food and feed production

- Mining and mineral processing

- Pharmaceutical manufacturing

Advantages

- High accuracy and repeatability

- Recipe-based automatic production

- Material traceability

- Data logging and reporting

- Remote diagnostics and support

Product Features

Precise Weighing

High-precision load cell systems with ±0.1% accuracy minimize material waste.

PLC Automation

PLC-controlled full automation with recipe-based production eliminates errors and reduces operator dependency.

Multi-Material

Simultaneous weighing and dosing of 10+ different materials, flexibility in complex mix formulations.

Data Monitoring

SCADA integration and data recording system for production reports, quality traceability and performance analysis.

Technical Specifications

Weighing Accuracy ±0.1% - ±0.5%

Capacity 10 kg - 5000 kg scales

Control PLC + HMI touch panel

Material Count 1-12 independent dosing channels

Communication SCADA, Modbus, Profibus

Certificate OIML R76 trade-approved weighing