Polyester Dosing System

Fiber additive systems specially designed for Stone Mastic Asphalt (SMA) mixtures.

- ✓ Automatic Weighing

- ✓ Easy Integration

- ✓ Precise Control

- ✓ Homogeneous Distribution

Polyester Dosing System (Fiber Additive System)

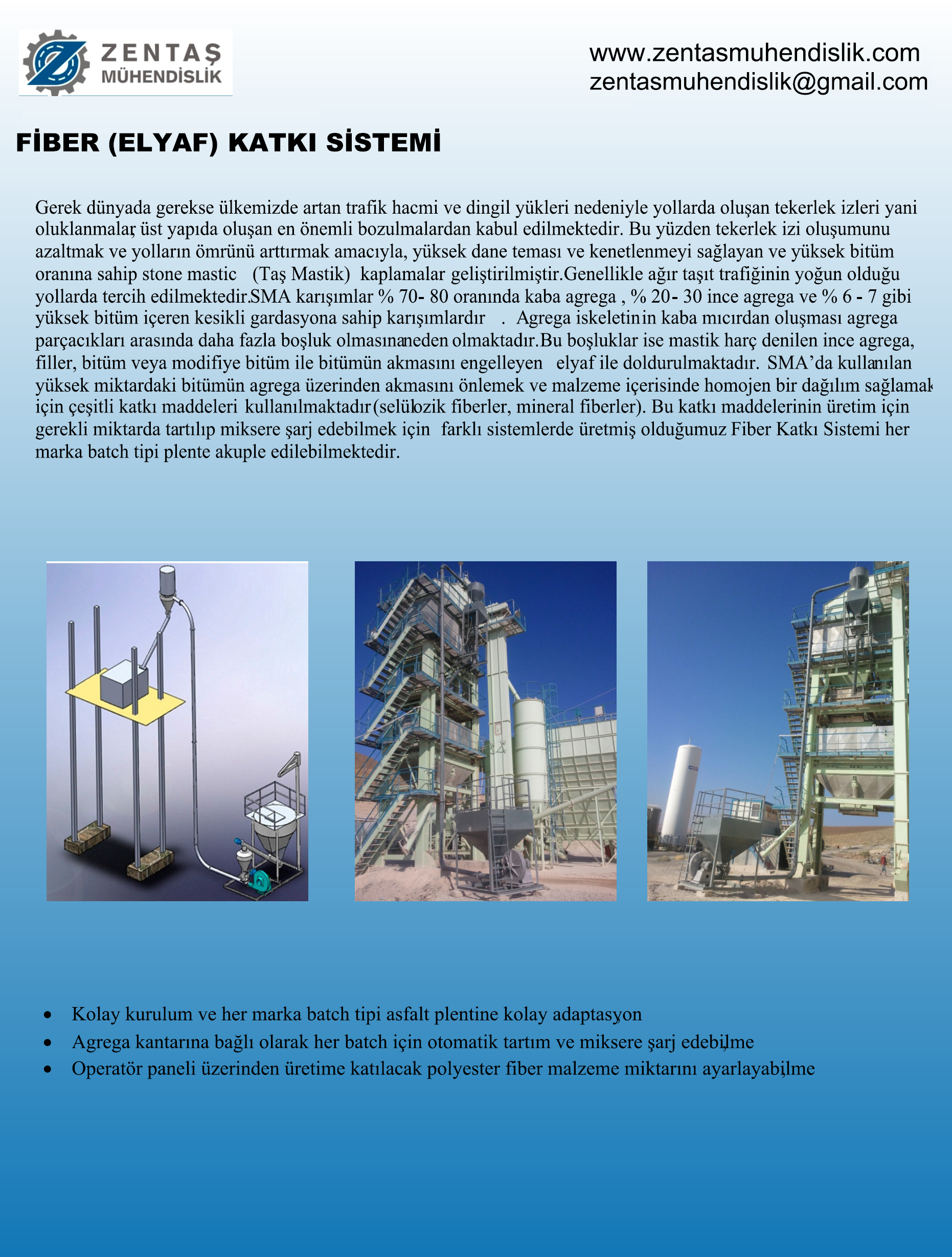

Due to increasing traffic volume and heavy axle loads, wheel tracking on roads causes significant pavement deterioration. Stone Mastic Asphalt (SMA) mixtures developed to prevent this provide high stone-on-stone contact, interlocking and high bitumen ratio.

SMA Mix Properties

- 70–80% coarse aggregate, 20–30% fine aggregate

- 6–7% high bitumen content

- Coarse gravel skeleton with more voids

- Voids filled with mastic mortar (fine aggregate, filler, bitumen or modified bitumen) and fiber

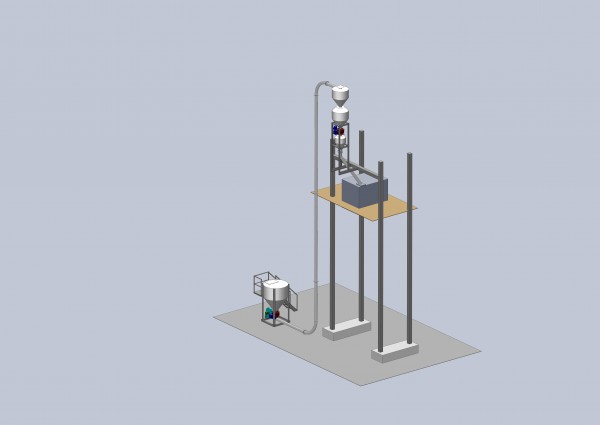

Fiber Additive System Features

- Easy installation, adaptation to any brand batch-type asphalt plant

- Automatic weighing linked to aggregate scale and charging to mixer

- Adjust polyester fiber amount via operator panel

- Homogeneous fiber distribution prevents bitumen drain-down

- Compatible with both polyester and cellulose fibers

Product Features

Automatic Weighing

Precise fiber dosing with automatic weighing system linked to aggregate scale prevents manual errors and material waste.

Easy Integration

Fast and easy adaptation to any brand batch-type asphalt plant, plug-and-play solution for existing facilities.

Precise Control

Adjust polyester fiber amount from operator panel, flexible dosing management according to mix.

Homogeneous Distribution

Direct charging system to mixer ensures homogeneous distribution of fibers in asphalt mix, prevents bitumen drain-down.