Mass-Produced Products

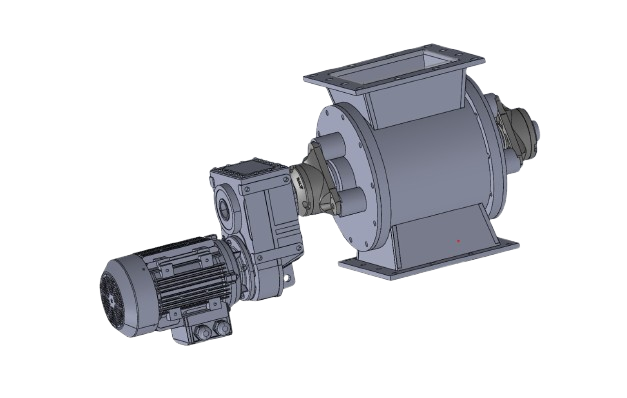

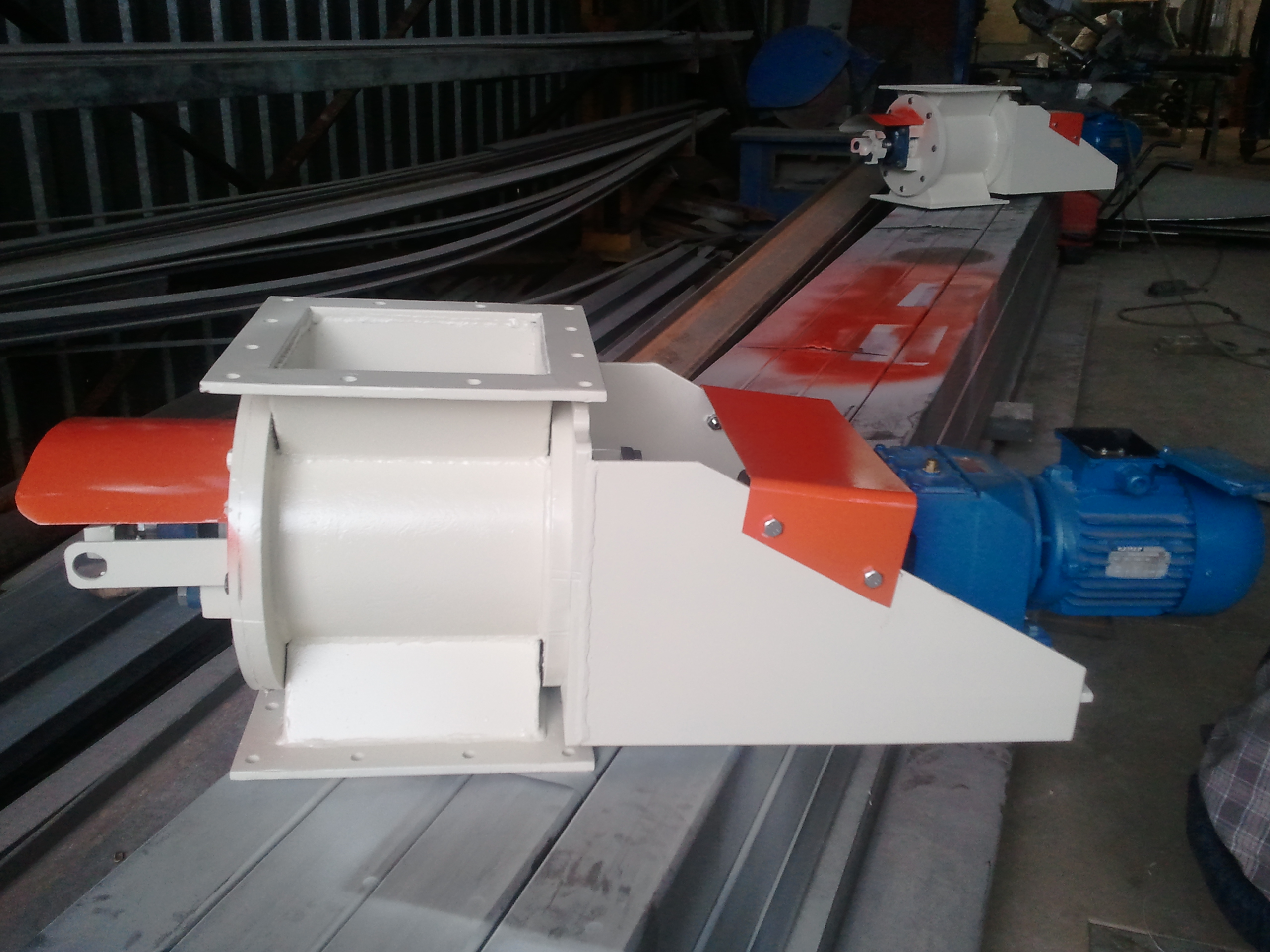

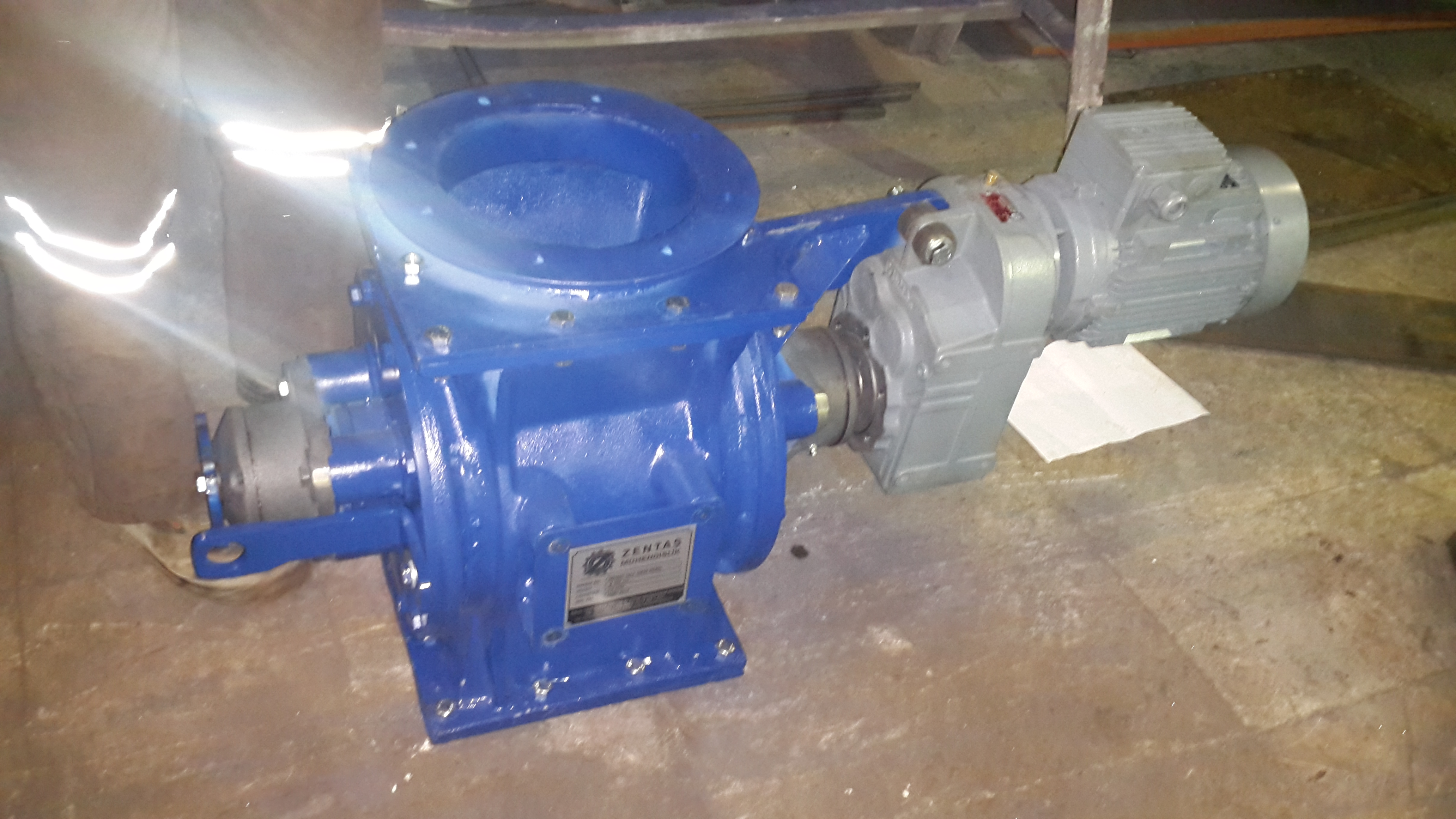

Star Feeder / Rotary Valve / Airlock

Airlock solutions for pneumatic conveying systems and dust collection systems.

- ✓ Airlock Function

- ✓ High Capacity

- ✓ Pressure Resistance

- ✓ Versatile Use

Star Feeder / Rotary Valve / Airlock

A rotary valve or airlock is equipment that transports material in chambers between a rotating rotor and housing,

while maintaining the pressure differential between two environments.

Typically used in:

- Pneumatic conveying systems

- Dust collection systems

- Silo discharge

- Filter outlets

- Feeding lines

Key Features of Rotary Valves

| Feature | Description |

|---|---|

| Main Function | Prevent air or gas leakage during material transfer (acts as an airlock). |

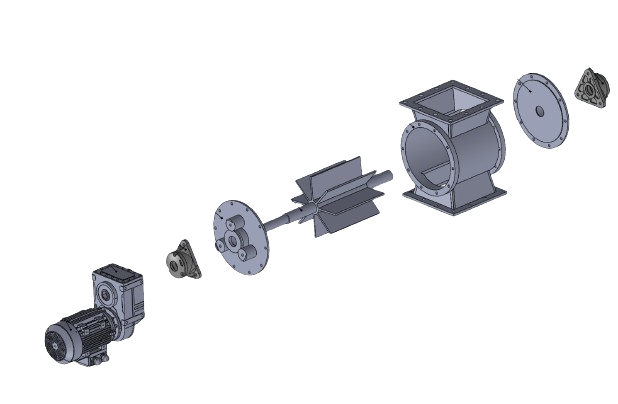

| Working Principle | As the rotor rotates inside the housing, material fills between the vanes. During rotation, this material is discharged from the bottom outlet. Air passage between upper and lower sections is minimal. |

| Construction Material | Usually manufactured from cast iron, stainless steel or carbon steel. |

| Rotor Type | Can be 6, 8 or 10 vane. Some models have rubber or teflon coated vanes. |

| Sealing | Low tolerance clearances on side surfaces; supported by seals or air curtain if needed. |

| Drive System | Driven by electric motor + gearbox combination. |

| Capacity | Depending on size, provides material flow from a few liters to hundreds of liters per minute. |

| Pressure Resistance | Generally operates air-tight at pressure differentials up to 1-1.5 bar (higher in some special types). |

| Connection Types | Can be flanged, square, round or custom connections. |

Application Areas

- Pneumatic conveying lines

- Dust collection systems (filter bottom outlet)

- Silo, bunker, cyclone outlets

- Food, chemical, cement, plastic, feed, energy sectors

Product Features

Airlock Function

Prevents air or gas leakage during material transfer and maintains pressure differential

High Capacity

Material flow from a few liters to hundreds of liters per minute

Pressure Resistance

Air-tight operation at pressure differentials up to 1-1.5 bar

Versatile Use

Used in pneumatic conveying, dust collection, silo discharge and filter outlets

Technical Specifications

Material Cast iron, stainless steel or carbon steel

Rotor Type 6, 8 or 10 vane

Pressure Resistance 1-1.5 bar (higher in special types)

Drive System Electric motor + gearbox

Connection Types Flanged, square, round or custom

Sealing Low tolerance gaps, sealed or air curtain

Star Feeder - Detailed View (Click on numbers for parts)